Heroes in machining shafts

Do you need precision shafts with machining? We are the shaft specialist in Europe and do not back down from any challenge! With our extensive machinery, we do everything in-house and can handle any machining operation.

With modern CNC lathe and milling machines, we make simple operation, such as chamfers and tapped holes, in a blink of an eye. And with the same ease, we make complex operations, such as flat edges, rejuvenations and keyways.

From single items to large quantities

We make machining from as little as a few items up to large serial quantities. So whether you are a small production company or a large machine builder, we are here for you!

From advice and drawing to production and packaging, we take everything off your hands. Contact our technical advisors and assure yourself of perfectly machined shafts.

Our heroes at work

We deliver top-quality precision shafts and machining. Through an efficient process, with fixed quality checks, you are guaranteed to get the shafts you need. In fact, our heroes work according to a set process. What does that look like? Take a quick look!

1. Cutting

We have at least 50 tons of precision shafts in stock in various steel grades, coatings and diameters with trade lengths of 6-7 meters. With cut-off machines we grind the shafts to exactly the right length and by default, all shafts are deburred manually.

Automatic feed and discharge lines ensure a fast, efficient and reliable process, perfect for serial quantities.

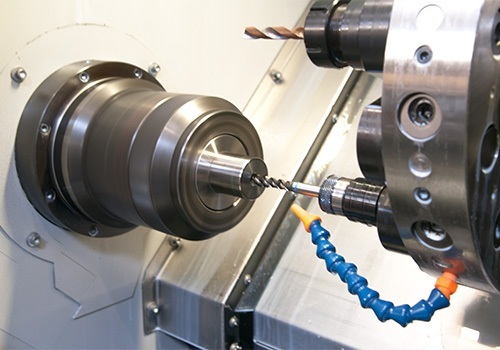

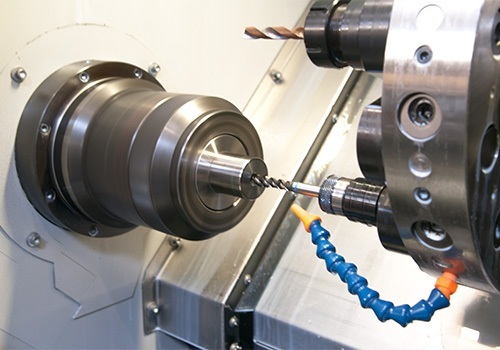

2a. CNC lathe and milling

With modern CNC machines, we can handle any operation. Almost any CNC machine can be used for a special application. And our Heroes of shaft machining know their machines like no other. That promises something!

For example, we have a CNC machine with which we can machine shafts up to a length op 2.5 meters.

We also have a CNC machine with double spindle, driven tooling and bar feeder ready for you. Perfect for quick machining on both sides of the spindles.

2b. Conventional lathe and milling

Not to forget, we also have conventional lathe and milling machines in our machinery, ideal for small quantities or unique machining operations. This also always make our heroes happy.

Whatever machining you need, we have the knowledge and resources to perform it quickly and cost-effectively.

3. Polishing

After machining, the shafts are polished. The polisher removes contamination and prevents oxidation of the machined part of the shafts. Also, during polishing, tiny indentations are removed from the surface of the shafts.

Longer shafts are accurately polished with our polishing machine. For larger series and smaller products, we use the deburring machine.

After polishing, we always enjoy shafts that shine!

4. Batching and packaging

With laser marking, we can apply a batch number. This keep your shafts traceable, throughout the production process.

Finally, the shiny shafts, provided with beautiful machining, end up in our packing department. Here, we carefully and meticulously pack your shafts and prepare them for shipment.

The only thing left is a signal to our carrier and... Before you know it, the shafts are on your doorstep!

We love machining shafts

And we do it to the fullest!

Quality Hero

Our quality manager, who is also a quality controller, monitors our processes and measures and monitors the quality of the shafts, including high-precision material analysis.

Technical brain

One of our shaft heroes put his technical brain to work and developed a measuring system that allows us to measure the length of the shafts with extreme accuracy.

Just what we needed, because we leave nothing to chance.

Working together

We do everything in-house. So you are assured of short lines, clear agreements, reliable products, and top-quality shafts.

Even if you need unique machining operations that require special tools, our heroes are there for you. Together we take on the challenge and make it a success!

Will our heroes also go to work for you?

Partner up?